SITUATION

Nasa Space Shuttle Atlantis

Maintenance and repair is routinely performed on the 40,000+ unique heat resistant tiles covering the Atlantis Space Shuttle. Tiles are usually repaired by removing them, filling the space with plaster, and then machining a new one based on the shape of the plaster. The new tiles must be made accurately to keep an airtight seal between them – any hot gasses trapped behind tiles during reentry could cause them to fail. The client needed to upgrade their tile-repair system to an automated, CAD-based solution.

SOLUTION

More than 40,000 unique tiles

The client contracted our team to develop a custom 3D scanning solution designed to help automate damage repair on the shuttle tiles. Our team worked with the client to develop a series of performance and tolerance goals needed for the project and evaluate potential scanning technologies.

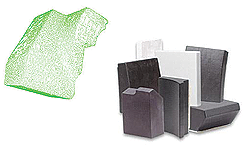

Our engineers developed a custom scanning system that fully automated the tile repair and fabrication process. The custom scanner uses a turntable to accurately scan and generate point cloud data for the tiles, which are then auto-surfaced using NURBS surfaces. The resulting CAD data is then used to machine an exact copy of the tile for replacement on the shuttle.

RESULTS

Custom Tile Scanning System

When our team started on the project, the client was using a manual tracer mill to literally trace a plaster impression (splash) while milling out a new part via mechanical linkages connected between the two.

The client has now been able to use our company’s custom 3D scanning system to automatically generate replacement tiles, lower labor costs and repair time, and generate CAD data documenting the legacy shuttle tiles. The client has since upgraded the equipment and is now using it for other applications such as accident reconstruction.