SITUATION

Truck Armor Kit

The vast amount of supplies being sent into Iraq has been key to the U.S. Military’s efforts in the region. Convoys of trucks loaded with supplies have been entering Iraq from Kuwait for the past several years; however, the lightly armored trucks offer very little protection for the drivers against projectiles and explosives. This client was contracted to develop armor kits for several models of trucks to ensure the safety of the drivers. However, CAD data was not available to aid in the design process.

The conventional method of capturing the shape of the trucks is templating, a process that lacks the efficiency and accuracy of 3D scanning. The client needed a solution that could accurately capture their as-built trucks.

SOLUTION

3D Scanning

The client contracted with our company to scan and compare the shape of several models of Mercedes and Volvo trucks. Our team used the Konica Minolta VIVID 9i in conjunction with photogrammetry to generate scan data of the truck cabs. Our team reverse engineered this scan data to create CAD data of the entire cab, which included the critical locations of the door sills, frames, and bolt-holes. These locations were necessary to ensure the precise fitting of the armor kits to the trucks.

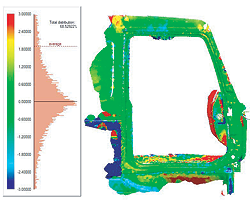

The scan data was then overlaid and the deviations were recorded and compiled into a colormap comparison. The client used these colormaps to determine which make and model truck would be used for up-armoring, as well as ensuring the similarities between the different truck models.

RESULTS

Colormap Report

Our company’s scanning services significantly shortened the prototyping process from three weeks to three days. Saving this much time allowed the client to quickly and accurately start production on armor kits, which have resulted in a massive decrease of driver injuries since their installation.

“Your services far exceeded our expectations for a 3D scanning and engineering company. Thanks to your engineers, our new armor kits fit the trucks perfectly on the first try! We benefited from a significant cost savings using 3D scanning, which reduced our prototyping time significantly.” – client’s Chief Designer.